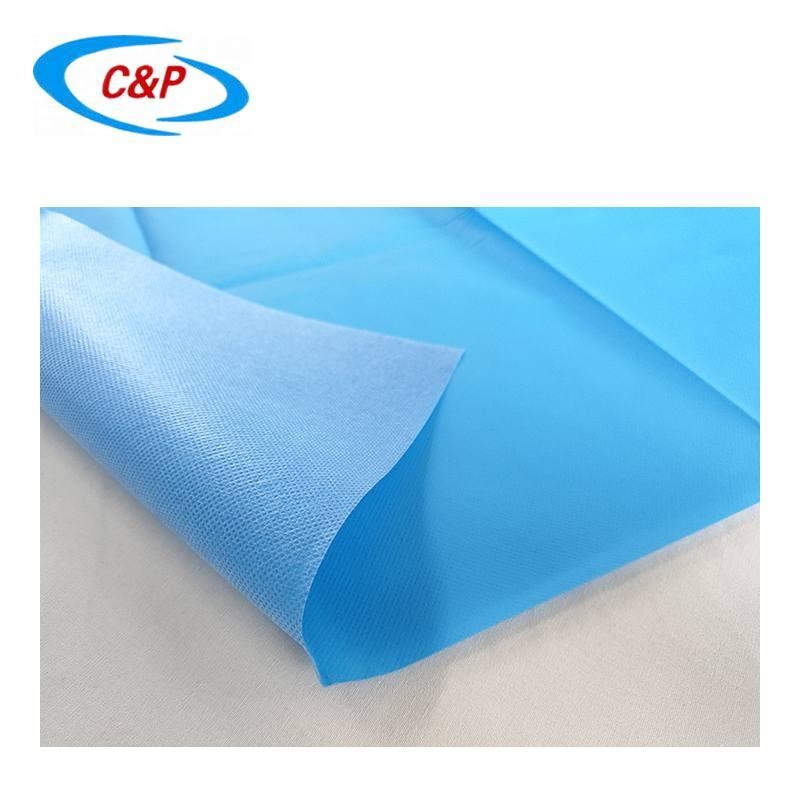

Application of non-woven fabrics in the medical field:

Non-woven fabrics are widely used in the medical field, covering many aspects from personal protection to medical equipment. The following is a specific introduction:

1. Personal protective equipment: Non-woven fabrics are widely used in the production of medical masks and surgical caps due to their excellent breathability and antibacterial properties. These products can not only effectively block the spread of viruses and bacteria, but also provide good comfort.

2. Disposable medical supplies: Non-woven fabrics also play an important role in the production of disposable surgical gowns and medical drapes. These disposable products can be discarded after use, effectively preventing the risk of cross infection.

3. Hygiene care products: Non-woven fabrics are also used in the production of hygiene care products such as maternity packs and diapers. These products are not only soft and comfortable, but also provide the necessary absorbency and breathability to help keep the skin dry and healthy.

4. Medical dressings: In the manufacture of medical dressings, non-woven fabrics are also widely used. Due to their good water absorption and breathability, dressings made of non-woven fabrics can accelerate the wound healing process and reduce the risk of infection.

5. Filter materials: Non-woven fabrics are also used as medical-grade filter materials, such as air filters for operating rooms and various liquid filtration devices. These filter materials can effectively remove particles and microorganisms in the air and ensure the cleanliness of the medical environment.

6. Packaging materials: Non-woven fabrics are also used for the packaging of medical devices, such as the outer packaging of surgical instruments and syringes. This packaging material can effectively isolate external pollution and ensure the sterility of the equipment.

7. Biomedical engineering: In the field of biomedical engineering, non-woven fabrics are used to make high-end medical devices such as artificial blood vessels and tissue engineering scaffolds. These products use the biocompatibility and degradability of non-woven fabrics to provide patients with better treatment options.

8. Drug delivery systems: Non-woven fabrics are also used in drug delivery systems, such as for the production of sustained-release drug patches. These patches can evenly release drugs onto the skin, improving the utilization rate and therapeutic effect of drugs.

In summary, the application of non-woven fabrics in the medical field is not limited to traditional protective and sanitary products, but also includes high-end biomedical engineering and drug delivery systems. With the advancement of technology and the increase in demand, the application prospects of non-woven fabrics in the medical field will be broader.